Stability and Shelf Life of Medical Device

Duration : 90 Minutes

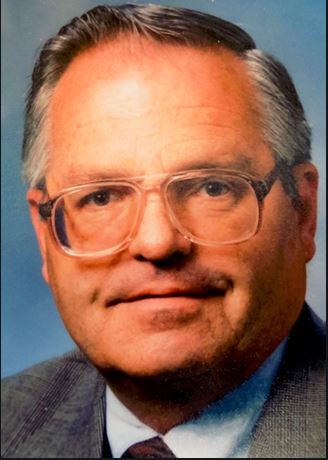

John E. Lincoln,

John E. Lincoln, is Principal of J. E. Lincoln and Associates LLC, a consulting company with over 38 years experience in U.S. FDA-regulated industries, 24 as an independent consultant. John has worked with companies from start-up to Fortune 100, world wide. He specializes in quality assuranc Read more

This webinar will cover all relevant regulatory requirements (CFR, FDA, ISO, ASTM and European) for establishing the stability and determining the shelf-life of medical devices. Attendees will gain a better understanding of the design control process for designing medical devices.

Course Objective:

New or modified devices must show no decline in performance affecting device safety and effectiveness over time, determining shelf-life (expiration date) prior to release to market. Since most polymers follow zero, first order Arrhenius behavior, samples of real-time aged product normally provide validation of the use of samples that have undergone accelerated aging. Testing to show that there is no decrease in device performance that may affect device safety or efficacy over time is gathered during testing of the accelerated-aging group and the results are normally validated when compared to the required testing of samples aged in “real-time”. However, the products are allowed to proceed to market based on shelf-life determination using accelerated aged products.

Samples used in both the accelerated and real-time groups should represent normal product and processing, including undergoing sterilization of product in their primary packaging. Packaging integrity/maintenance of sterility should be established as well. Understanding product characteristics critical for device safety and efficacy, user requirements (hospital use vs. military use and environmental extremes/physical stress) may increase understanding of device development, transfer from R&D to manufacturing and improve detection of quality or process issues.

Course Outline:

• CFR requirements, FDA, ISO, ASTM, European guidelines/standards that are applicable to the requirement for determination of shelf-life and stability for medical devices.

• Requirements and specific criteria necessary to design studies done on product that is aged using both real-time and accelerated aging conditions, parameters for establishing stability of the device and device packaging.

• Criteria used for assessing the stability of a specific device and all other relevant criteria to be included in the design of the stability protocol for the medical device/product packaging will be discussed.

• The data required for the initial release of a product to the market and the manner in which this initial expiration date may be extended will be discussed.

• The Design Control process and its’ importance to ensuring that the product is stable and adequate for its’ intended use over the shelf-life of the product.

• ISO 13485:2003 will be compared to the version of ISO 13485 that was revised in 2016 and will be implemented in 2019.

What You Get:

• Training Materials

• Live Q&A Session with our Expert

• Participation Certificate

• Access to Signup Community (Optional)

• Reward Points

Who Will Benefit:

• Quality personnel

• Validation personnel

• Engineers or others involved in device design or in the design control process

• Design control personnel

• Packaging engineers

• Stability testing personnel

• Compliance personnel

• Distributing/Shipping personnel

• Personnel responsible for process/product design

• Manufacturing personnel

Please reach us at 1-888-844-8963 for any further assistance or if you wish to register